Department Plant Engineering

Department Plant Engineering

(formerly Professor Dr.-Ing. Uwe Bracht, professorship currently not assigned)

Only the successful design and development of industrial value creation can secure our standard of living and the achievements of the social market economy in the long term. Production continues to form the backbone of a modern industrial, service and information society in global competition. Comprehensive knowledge and constantly new findings in the fields of factory planning and production organization are existentially necessary.

The entrepreneurial significance of factory planning and organization has increased in the same measure as the innovation cycles of products, manufacturing and logistics systems and work organization have shortened. In order to consolidate the existing market position or to gain competitive advantages, every company management must constantly analyze not only the product and the technology, but also the production structures, adapt them in good time to expected market developments and, if necessary, renew them.

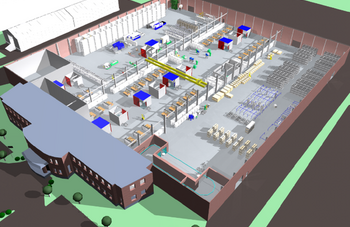

The increased demands on the design and adaptability of production structures in a turbulent environment require efficient project management and continuous computer-aided planning support.

A common systems engineering approach characterises the specialist areas of plant planning and logistics, whose technical, information-technical, organisational and economic questions must be answered in a holistic and forward-looking manner. The solution strategies include theoretical, planning and simulation aspects as well as the concrete design of process chains, organisational forms and procedures.

Due to ever shorter product life cycles and the growing individualization of products, the frequency and complexity of factory planning tasks is increasing. In addition, Industry 4.0 and the associated digitalization lead to new challenges in production and logistics. The digitally networked creation of value is a central aspect for planning and operation. The Digital Factory enables the continuous digital planning of factories and processes, thus creating an essential basis for Industry 4.0. Due to the increasing complexity of the plants, factories and logistics processes to be planned, the use of artificial intelligence for planning support is also being focused on. The known methods and tools of the Digital Factory are currently only transferable to these developments to a limited extent and must be adapted or further developed.